FINISHED PRODUCT MACHINES

Energy bars

Energy bars

Machines for the production of cereal and nut energy bars

MIA Food Tech machines allow you to create recipes based on cereals and binders (fats or fiber) with a manual, semi-automatic and automatic process.

In MIA Food Tech’s wide range of machines, you will find machines that are suitable for all types of processing of cereal bars.

ENERGY BARS

The machines

C1 AUTO + CUTTING TABLE

BAR Start-up Line

Turnkey line for artisanal snack bar production of up to 5,000 pcs/day

Easy Bars 100

Automatic energy bar lamination line

production of non-sticky snack bars up to 2,000 pcs/h

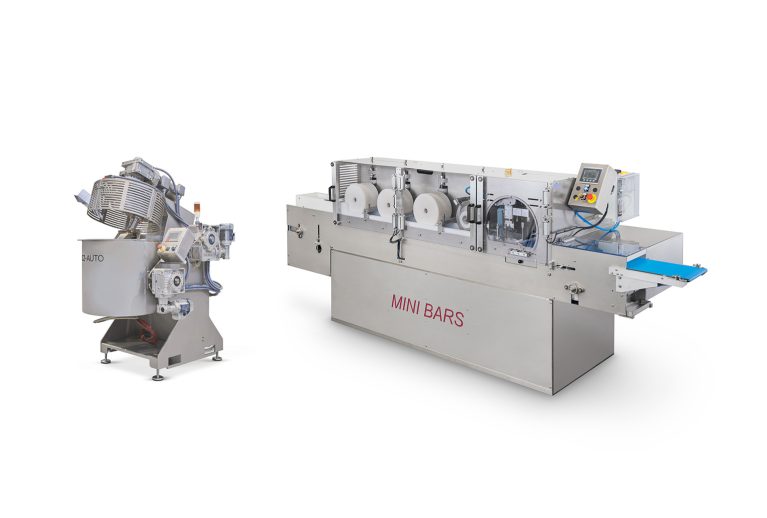

C2 AUTO + MINI BARS 130 - 150 - 250

Smart BAR Line

Turnkey line for semi-industrial snack bar production of up to 25,000 pcs/day

MINI BARS 150 COOL-WARM

Automatic energy bar lamination line

production of bars up to 3500 pcs/h + heating-cooling tunnel

MINI BARS 250 COOL-WARM

Automatic energy bar lamination line

production of energy bars up to 3,500 pcs/h + heating-cooling tunnel + separator

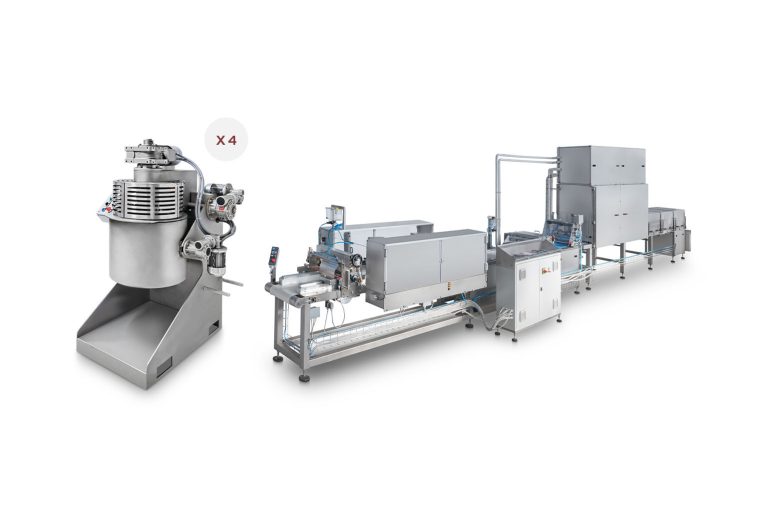

N.4 C1 AUTO + LC 240 o LC320

Professional SNACK BAR Line

Turnkey line for industrial snack bar production of up to 50,000 pcs/day

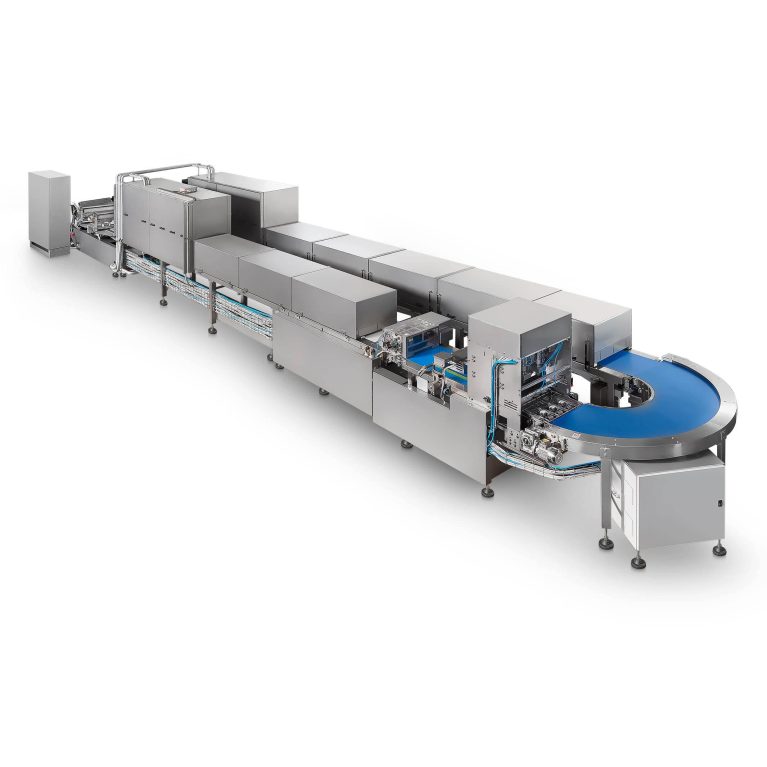

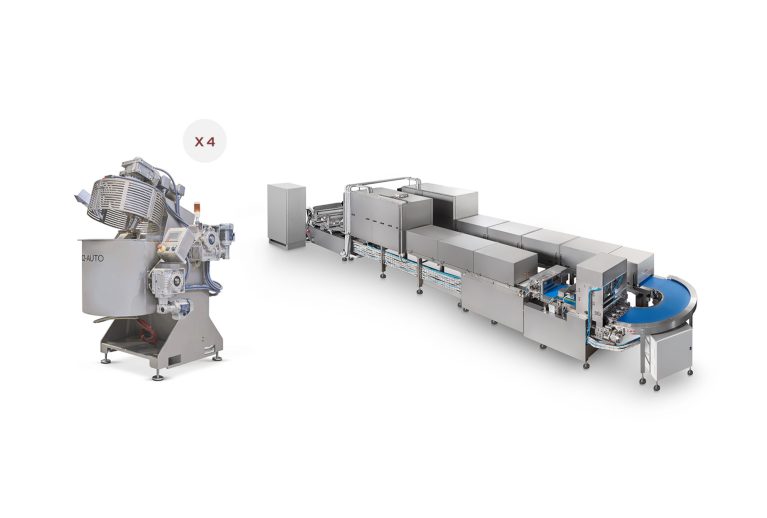

N.4 C2 AUTO + LC 320 o LC 420

Industrial SNACK BAR Line

Turnkey line for large-scale industrial snack bar production of up to 100,000 pcs/day

ENERGY BARS

Cookers

We offer a wide range of cookers with a capacity from 5 kg up to 40 kg.

Cookers that are suitable for cooking mixtures with automatic systems for the mixing/cooking of ingredients.

Various types of heating systems are available: gas, steam or electric. The machine can also be configured for the automatic unloading of the product.

Automatic lines for brittle

Daily production is about 10 kg/hour of product with a semi-automatic line.

We produce automatic lines for the unloading, spreading out, lamination and cutting of energy bars with product capacities varying from 40 kg/hour to 100 kg/hour.

We also produce cooling tunnels to combine with our systems, cutters or other systems, with working widths from 300 to 800 mm

The tunnels are sized in accordance with production process needs.

The tunnels are designed not only as cooling systems but also with systems for heating the air inside the tunnel.

Cutters

We produce a wide range of cutters (stand-alone) for finished products: bars, portions, etc.

MIA Food Tech manufactures its cutters in compliance with the safety standards for cutting operators, while achieving high quality, top speed and versatility in the resulting formats.

MIA Food Tech is constantly researching the best cutting technologies that respect safety requirements and reliability.

The technology applied ranges from traditional cutting with circular disc cutters to cutters with ultrasonic systems.