Features

- Machine made entirely of AISI 304 stainless steel

- Stainless steel structure for thorough and long-lasting cleaning

- Automatic head raising and tank tipping

- Mixing and cooking of different types of mixtures for brittle or snack bars

- Tank capacity from 30 to 90 liters depending on the model

Technical specifications

- Planetary mixer arm and/or with central blade and speed adjustment.

- “Bain marie” type electrical heating with temperature up to 230°C

- Optional “Industry 4.0” configuration

- Optional ethernet and/or remote connection

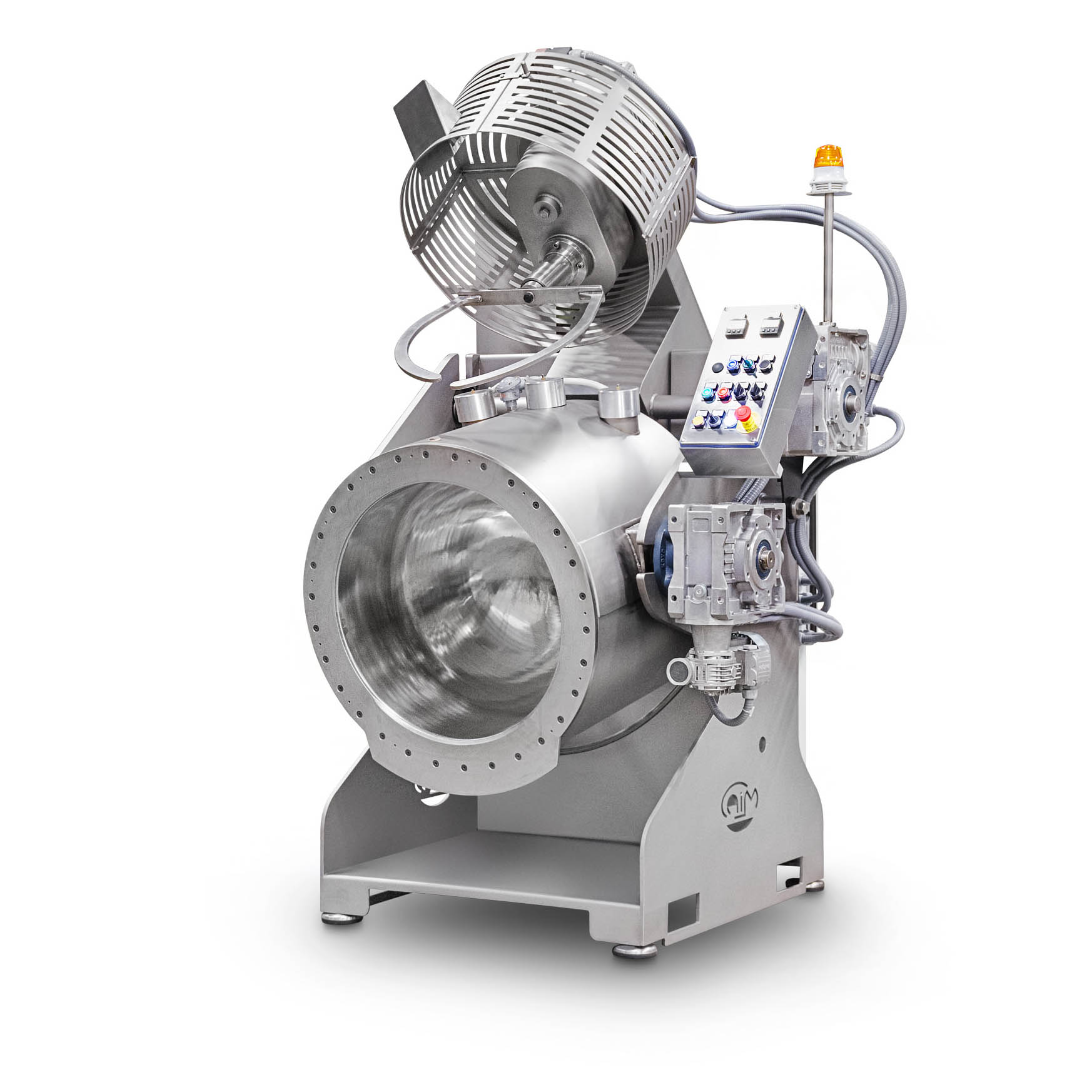

High temperature cooker

The MIA FOOD TECH cookers for snack bars/brittle are designed for cooking mixtures with the possibility of reaching very high temperatures (up to 230°C), but also able to work at room temperature.

Cooker features

These machines are fitted with an electrical heating system with heating elements in a diathermic oil bath, with a jacketed tank for “bain-marie” cooking.

The machine head can be automatically raised to allow the rotation of the cooking tank.

The cooking tank can be automatically tipped for safe and easy product unloading.

Double blade mixer arm with planetary system and adjustable rotation speed from 10 to 30 rpm.

The frame, safety guards and all the machine components are made of AISI 304 stainless steel for easier and long-lasting cleaning and sanitization.

It features a computer system for setting the temperature and programming the heating and cooking time.

Using the cooker

The machine can be brought up to temperature via a software program with a delay time of about 30 minutes or alternatively, via automaticprogramming with a day/night cycle.

When the pre-set degrees have been reached, the binder is poured into the tank and left to cook until the temperature is reached. The solid component is then added and only then is the cooking time calculated which varies from 5 to 15 minutes depending on the desired product.

To monitor the process, a timer can be set which will warn you when cooking has finished with an acoustic and light signal.

The product can be easily unloaded by automatically tipping the cooking tank.

Cooker configurations

C1 AUTO / CT1 AUTO Cooker

Tank capacity: 30 liters

Electrical power: 8Kw 400V Three-phase

Production: 10-15 kg of brittle or 7-10 kg of mixture for cereal bars

C2 AUTO / CT2 AUTO Cooker

Tank capacity: 60 liters

Electrical power: 14Kw 400V Three-phase

Production: 20-30 kg of brittle or 14-25 kg of mixture for cereal bars

C3 AUTO Cooker

Tank capacity: 90 liters

Electrical power: 19Kw 400V Three-phase

Production: 25-40 kg of mixture for cereal bars

Nougat Cooker

The cookers can be fitted with a kit for the production of nougat which includes a mixer arm with a central blade to replace the planetary mixer arm, special gearbox with a specific reduction ratio and a more powerful motor.

Cleaning the cooker

Clean the cooking tank with hot water and a sponge or steam between batches or at the end of the work shift.

Frequent use: washing with about 10 liters of water, heated and mixed by the rotating arm

Deep cleaning: washing with about 30 liters of water, heated and mixed by the rotating arm, finishing and removing any drops with a damp cloth

Brittle & Energy bars

High temperature cooker

for the production of energy bars and brittle