Features

- Machine made entirely of AISI 304 stainless steel

- Food-grade plastic feeding hopper and lamination rollers

- Production capacity 1,200-1,800 bars/h

- Line speed and cycle parameter settings via the HMI panel

Technical specifications

- Dimensions 2750 X 750 x 1450 (H) mm

- Fixed bar length (to be determined during the order stage)

- Bar width change via the HMI panel

- Guillotine transverse cutting unit with pneumatic action.

- Optional installation of ultrasonic cutting unit

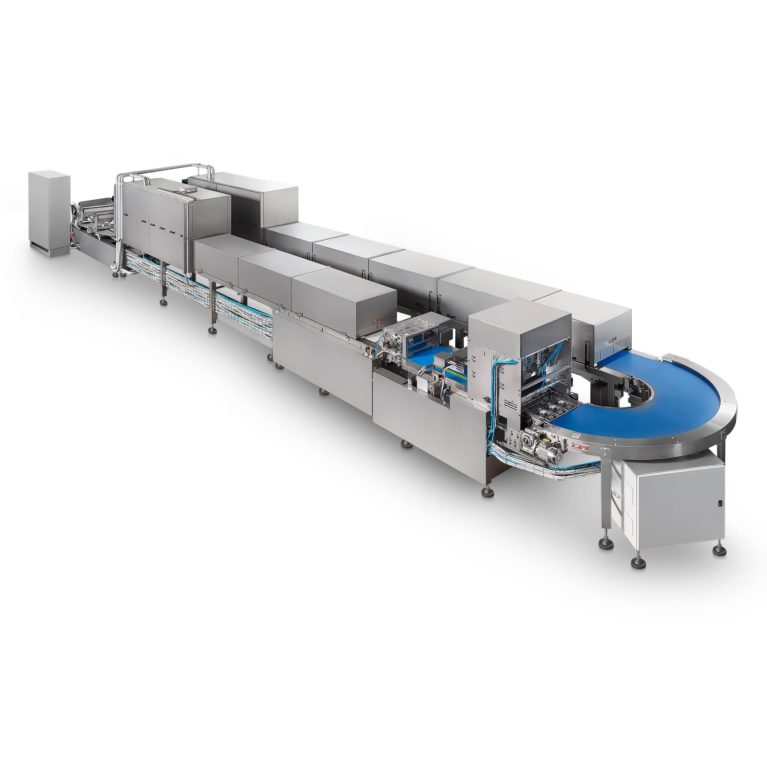

Automatic system for the production of cereal bars, soft bars, brittle bars, protein and high protein bars, particularly suitable for start-up projects with a production rate of about 1200-1800 bars/hour according to the type of bars produced.

The machine laminates and cuts the bars with the production speed and bar size set via the HMI operator panel.

The line is fitted with two Teflon lamination rollers which form a film on the product, a smooth finishing roller and a transverse cutting unit which can be the traditional guillotine version or ultrasonic for extra sticky products.

An operator loads the product into a food-grade plastic hopper while the machine automatically carries out all the bar processing steps.

A second operator located at the machine output removes the snack bars and places them on special trolleys for the subsequent processes (chocolate coating, decoration, etc.) or directly onto the packaging machine.

This type of automated line is usually combined with two of our C1 AUTO 30-liter cooker models or our C2 AUTO 60-liter cooker model.

Cleaning the laminator

Clean the cutting unit with a damp sponge when necessary, and with hot water and a sponge or steam at the end of the work shift.

Energy bars

Automatic energy bar lamination line

production of non-sticky snack bars up to 2,000 pcs/h