FINISHED PRODUCT MACHINES

Brittle

Brittle

Machines for the production and processing of brittle

MIA Food Tech’s machines can produce brittle with whole or chopped nuts, sugar and the optional addition of glucose. Our range of machines reduces operator fatigue and mechanizes the steps that are often carried out manually.

BRITTLE

The machines

C1 AUTO + CUTTING TABLE

BAR Start-up Line

Turnkey line for artisanal snack bar production of up to 5,000 pcs/day

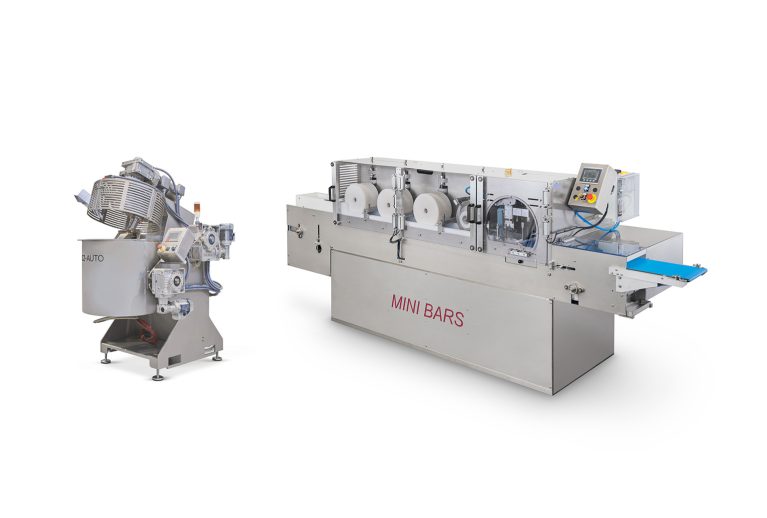

C2 AUTO + MINI BARS 130 - 150 - 250

Smart BAR Line

Turnkey line for semi-industrial snack bar production of up to 25,000 pcs/day

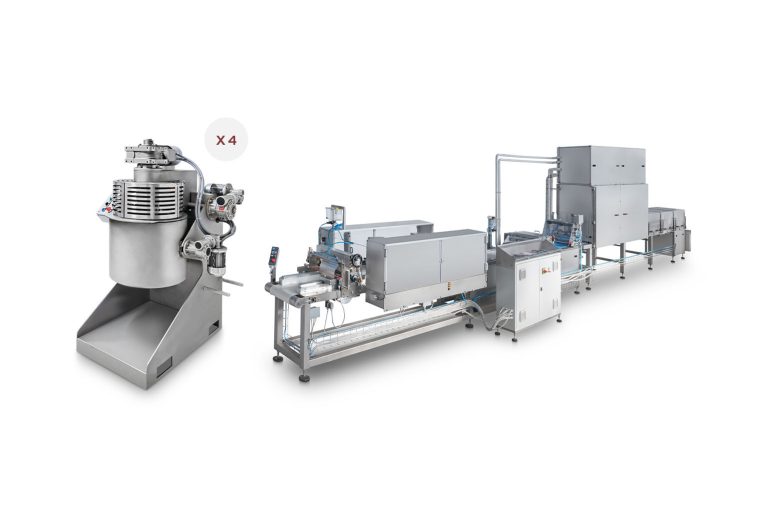

N.4 C1 AUTO + LC 240 o LC320

Professional SNACK BAR Line

Turnkey line for industrial snack bar production of up to 50,000 pcs/day

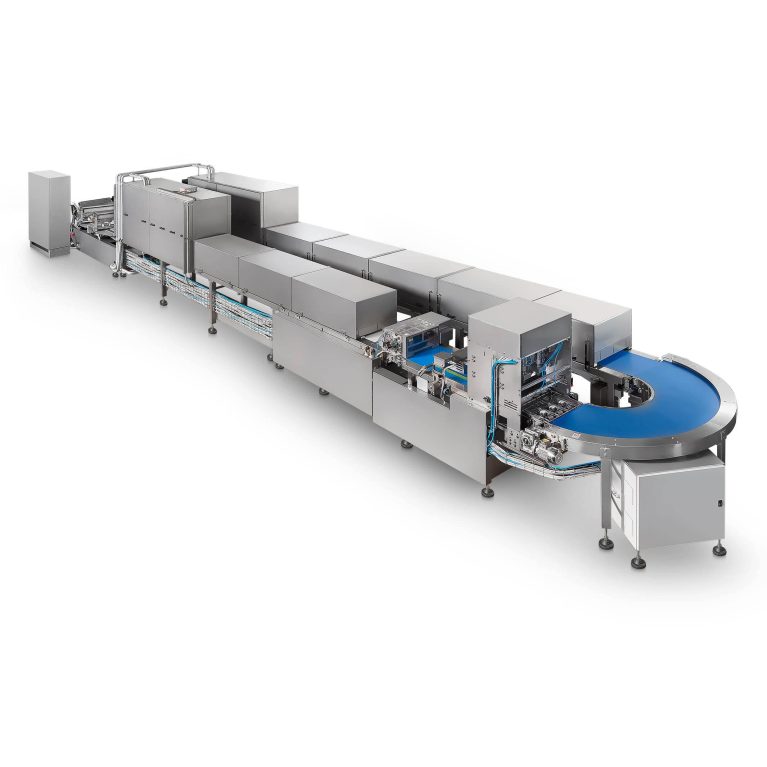

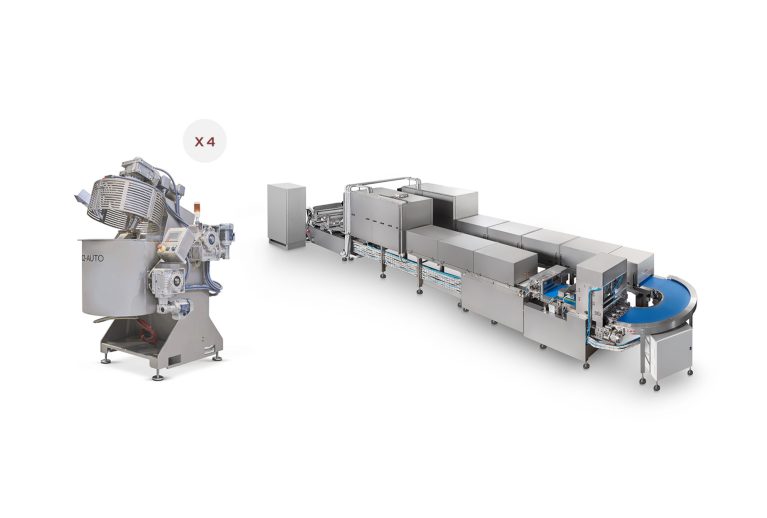

N.4 C2 AUTO + LC 320 o LC 420

Industrial SNACK BAR Line

Turnkey line for large-scale industrial snack bar production of up to 100,000 pcs/day

Types of processing

The range of machines for brittle and snack bars includes:

- roasting and sorting of nuts

- chopping of nuts

- glucose maintenance

- cooking with a capacity from 5 to 35 kg

- unloading and manual or automatic spreading out of the product

- semi-automatic or automatic cutting into various shapes

- chocolate enrobing

- product alignment and packaging

Our strengths

Cookers

With regard to the first category, Miaft stands out from the competition with the introduction of a bain-marie heating system featuring electric heating elements in diathermic oil, as opposed to the more common gas heating used by our competitors. Electric heating ensures excellent flexibility as it is possible to set a precise cooking temperature. It is also a much safer alternative for the operator, avoiding the presence of naked flames.

Other benefits of our cookers include the automatic raising of the machine head and tipping of the cooking tank, thus avoiding all physical contact by the operator with the hot product.

Manual systems

Our range of manual systems offers a number of benefits compared to market alternatives. The greatest innovation lies in the possibility of installing a heating/cooling unit on the table, thus allowing the working temperature to be set from 10° to 70°C.

With this setting the manual system can be adapted to the production of all types of brittle and/or energy bars, including sesame which, by its nature, is complicated to process as it tends to crystallize rapidly making the lamination of the product particularly challenging.

By setting the temperature up to 70°C, the crystallization process is slowed down, allowing the operator to correctly spread the product out on the table.