Macchine per prodotto finito

Torrone

Torrone

Macchinari per la lavorazione e produzione del Torrone

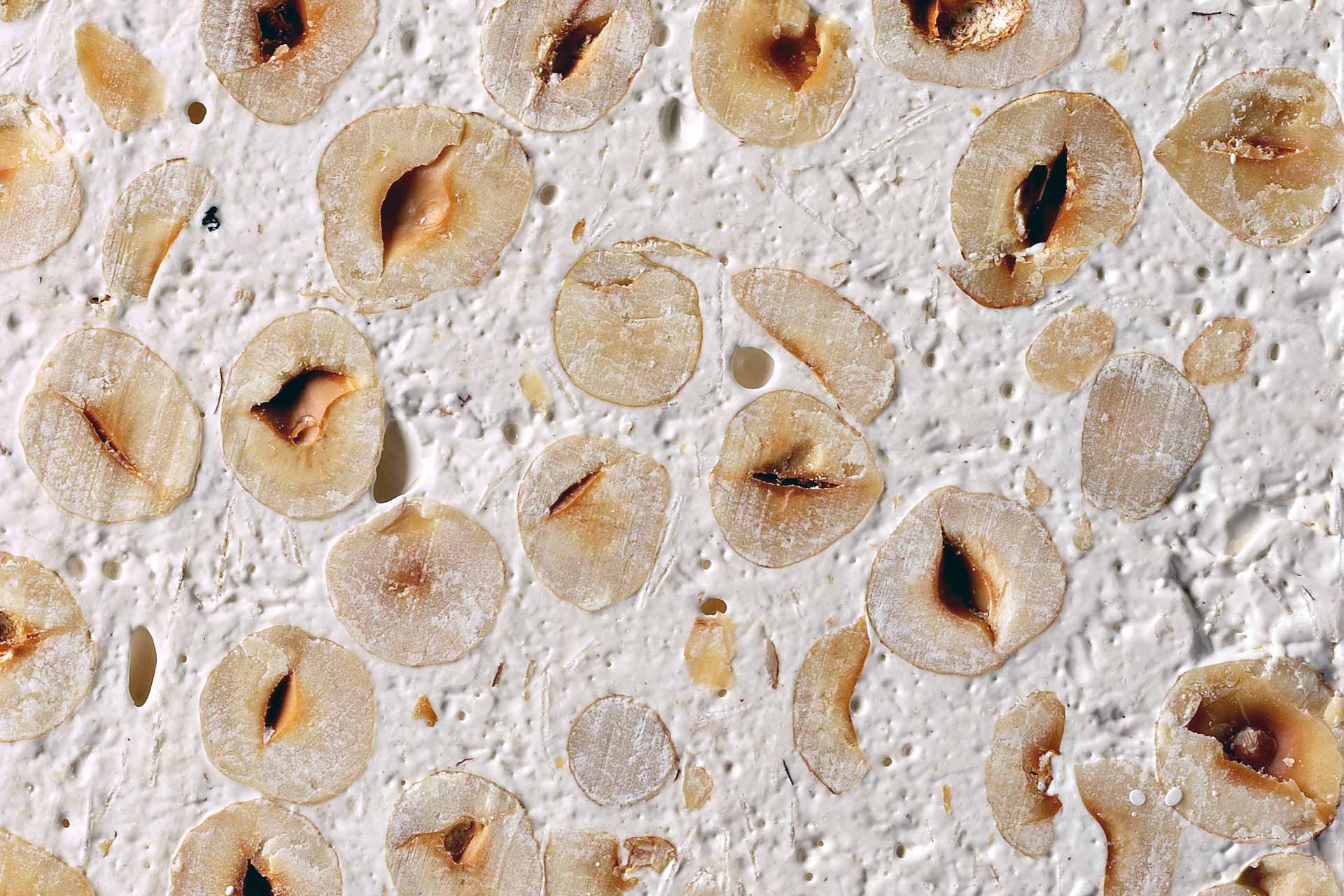

I macchinari MIA Food Tech permettono di realizzare croccante e torrone con processo manuale, semi-automatico ed automatico. Nella seguente gamma di macchinari potrete trovare macchine idonee per tutti i tipi di lavorazione su torroni e croccanti, con tecnologie innovative che facilitano il lavoro degli operai, riducendo la fatica e la durata dei processi.

Torrone

I macchinari

EASY 250, EASY 350, EASY 400

Taglierina manuale stecche

per il taglio delle stecche di torrone partendo da uno stampo

Taglierina ad ultrasuoni

per torrone, torte di pasticceria, pan di spagna

TORRONE

I macchinari MIA Food Tech permettono di realizzare croccante e torrone con processo manuale, semi-automatico ed automatico.

Nella svariata gamma di macchinari MIA Food Tech potrete trovare macchine idonee per tutti i tipi di lavorazione su torroni e croccanti.

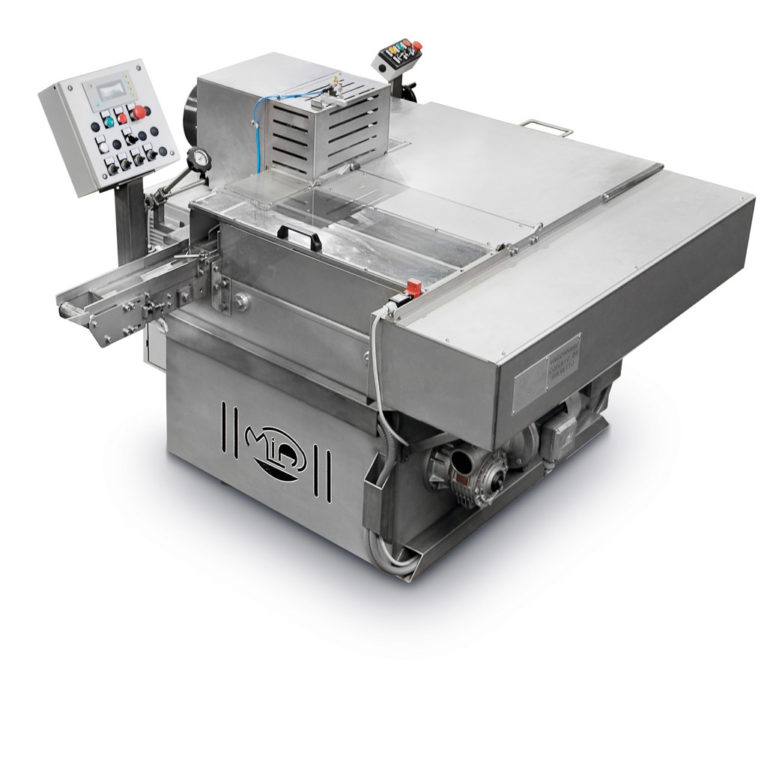

MIA Food Tech ha una vasta gamma di cuocitori che vanno da una capacità di 10 kg. fino ad arrivare alla capacità di 120 kg.

Cuocitori adatti alla cottura di impasti con sistemi automatici di miscelazione/ cottura degli ingredienti.

Il riscaldamento può essere di diverso tipo : gas, vapore o elettrico mentre la macchina può avere la possibilità di eseguire lo scarico in automatico del prodotto.

MIA Food Tech può fornire macchinari semiautomatici per la stenditura o la pressatura omogenea dell’impasto negli stampi (torrone) o tavoli (croccante) da utilizzarsi nei processi manuali o semiautomatici.

MIA Food Tech, realizza un’ ampia gamma di taglierine (stand alone) per prodotti finiti: barrette, porzioni, torte, torroncini, caramelle.

MIA Food Tech costruisce le proprie taglierine rispettando le normative di sicurezza per l’operatore addetto al taglio ma ottenendo comunque alta qualità di taglio, elevata velocità di taglio, versatilità dei formati ottenibili.

MIA Food Tech è sempre alla ricerca delle migliori tecnologie di taglio rispettando i requisiti di sicurezza e affidabilità.

La tecnologia applicata va dai tagli tradizionali con taglierine a dischi circolari fino a taglierine con sistema ad ultrasuoni.

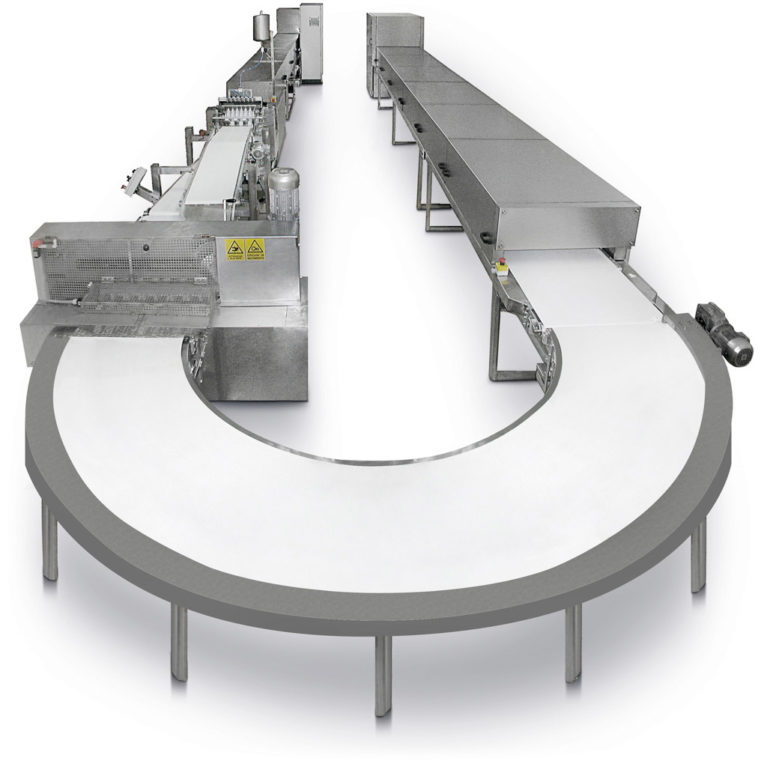

MIA Food Tech realizza linee automatiche per lo scarico, stenditura, laminazione e taglio di torroni e croccanti con capacità variabili da 100 kg/ora a 500 kg/ora di prodotto.

MIA Food Tech realizza tunnel di raffreddamento da abbinarsi ai ns. impianti, alle nostre taglierine o anche ad altri impianti, con larghezze utili da 300-400-600-800 mm. e lunghezze da 10 m a 30 m.

I tunnel vengono dimensionati in base alle esigenze del processo produttivo.

Se richiesto possono essere anche realizzati tunnel di raffreddamento sviluppati in verticale per diminuire gli ingombri negli stabilimenti.

I tunnel vengono anche progettati oltre a sistemi di raffreddamento con sistemi per il riscaldamento e la deumidificazione del aria interna del tunnel.

I prodotti ottenuti dai macchinari di processo possono inoltre essere ricoperti di cioccolato con ricopritrici installate in linea sui nostri impianti produttivi.

Le ricopritrici sono anche fornite di temperatrici per cioccolato. Sono disponibili ricopritrici/temperatrici con reti da 400-600-800.