FINISHED PRODUCT MACHINES

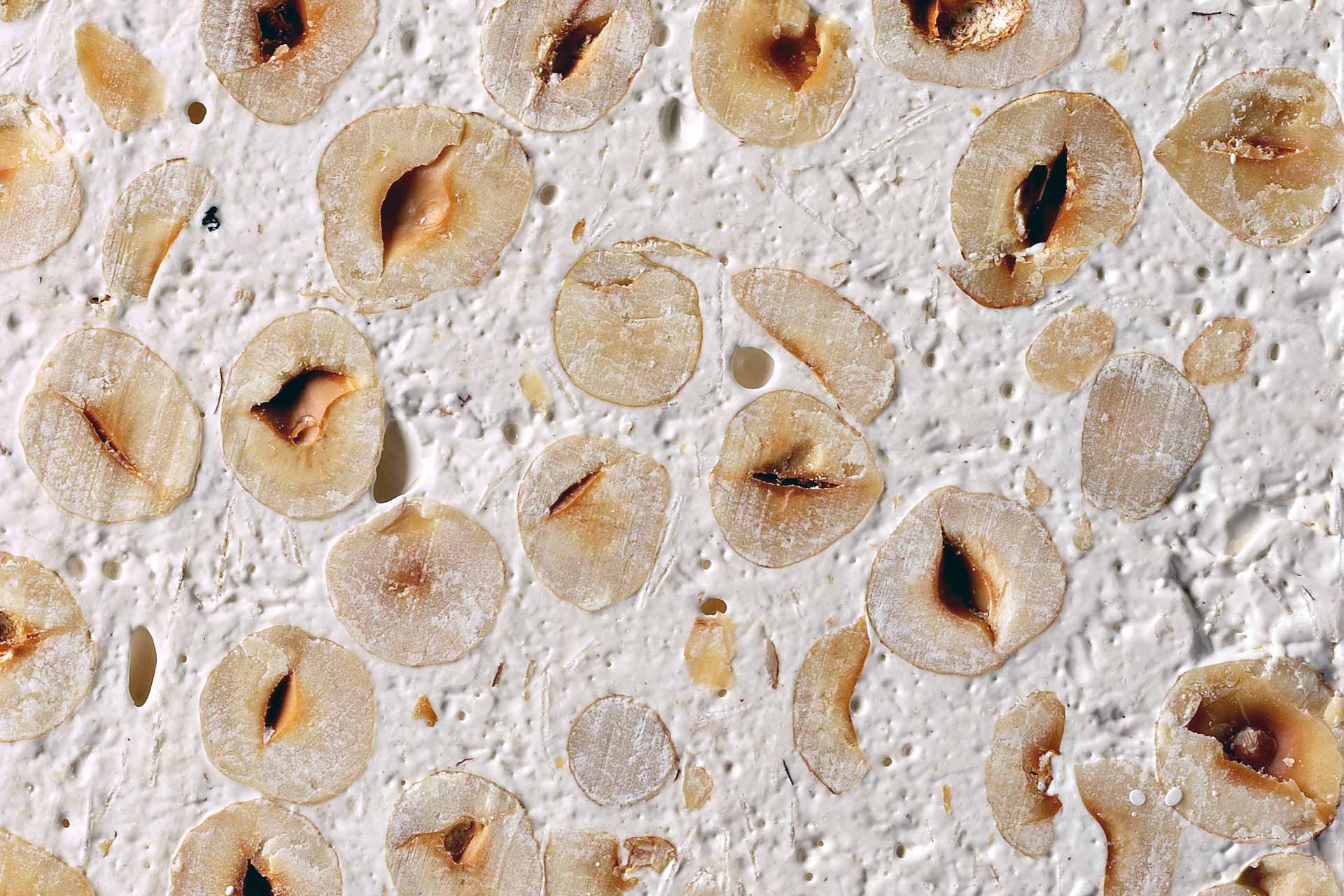

Nougat

Nougat

Machines for the production and processing of nougat

MIA Food Tech machines allow you to create brittle and nougat using a manual, semi-automatic and automatic process. The following range features machines that are suitable for all types of processing of nougat and brittle, with innovative technologies that make the operators’ work easier by reducing fatigue and the duration of the process.

NOUGAT

The machines

No products found

NOUGAT

MIA Food Tech machines allow you to create brittle and nougat using a manual, semi-automatic and automatic process.

In MIA Food Tech’s wide range of machines, you will find machines that are suitable for all types of processing of nougat and brittle.

MIA Food Tech has a wide range of cookers with a capacity from 10 kg up to 120 kg.

Cookers that are suitable for cooking mixtures with automatic systems for the mixing/cooking of ingredients.

Various types of heating systems are available: gas, steam or electric. The machine can also be configured for the automatic unloading of the product.

MIA Food Tech can supply semi-automatic machines to spread out and press the mixture evenly into molds (nougat) or on tables (brittle) for use in manual or semi-automatic processes.

MIA Food Tech produces a wide range of cutters (stand-alone) for finished products: bars, portions, cakes, nougat bites, candy, etc.

MIA Food Tech manufactures its cutters in compliance with the safety standards for cutting operators, while achieving high quality, top cutting speed and versatility in the resulting formats.

MIA Food Tech is constantly researching the best cutting technologies that respect safety requirements and reliability.

The technology applied ranges from traditional cutting with circular disc cutters to cutters with ultrasonic systems.

MIA Food Tech produces automatic lines for the unloading, spreading out, lamination and cutting of nougat and brittle with product capacities varying from 100 kg/hour to 500 kg/hour.

MIA Food Tech also produces cooling tunnels to combine with our systems, cutters or other systems with working widths from 300-400-600-800 mm and lengths from 10 m to 30 m.

The tunnels are sized in accordance with production process needs.

On request, we can also produce vertical cooling tunnels to decrease the system footprint in the customers’ facility.

The tunnels are also designed not only as cooling systems but also as systems for heating and dehumidifying the air inside the tunnel.

The products obtained using the processing machines can also be coated in chocolate by in-line enrobing machines installed on our production systems.

The enrobing machines can also temper the chocolate. Enrobing/tempering machines are available with 400-600-800 mesh sizes.